A blower fan is a device that efficiently and effectively enhances the flow of air within a workspace by making use of an impeller, airfoils (blades), and an electric motor. The main use of blower fans is as a permanent addition that increases airflow in a workspace and eliminates dirt, dust, and particulate matter. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

At DeKalb Blower, we specialize in the design and manufacturing of high-quality blowers that deliver exceptional performance and reliability. Our expertise lies in providing advanced airflow solutions tailored to meet the unique needs of diverse industries. By combining innovative engineering with precision craftsmanship, we create blowers that excel in efficiency, durability, and functionality.

Since 1959, Northern Blower® has offered a wide range of industrial blowers and fans including centrifugal fans, axial fans, swingout fans and custom made fans. Contact us today for information on our quality fans, blowers and equipment. We are committed to the manufacture of a rugged, long-lasting product delivered on time, every time. AMCA Member and ISO 9001:2000 Registered.

More Blower Fan Manufacturers

What is a Blower Fan?

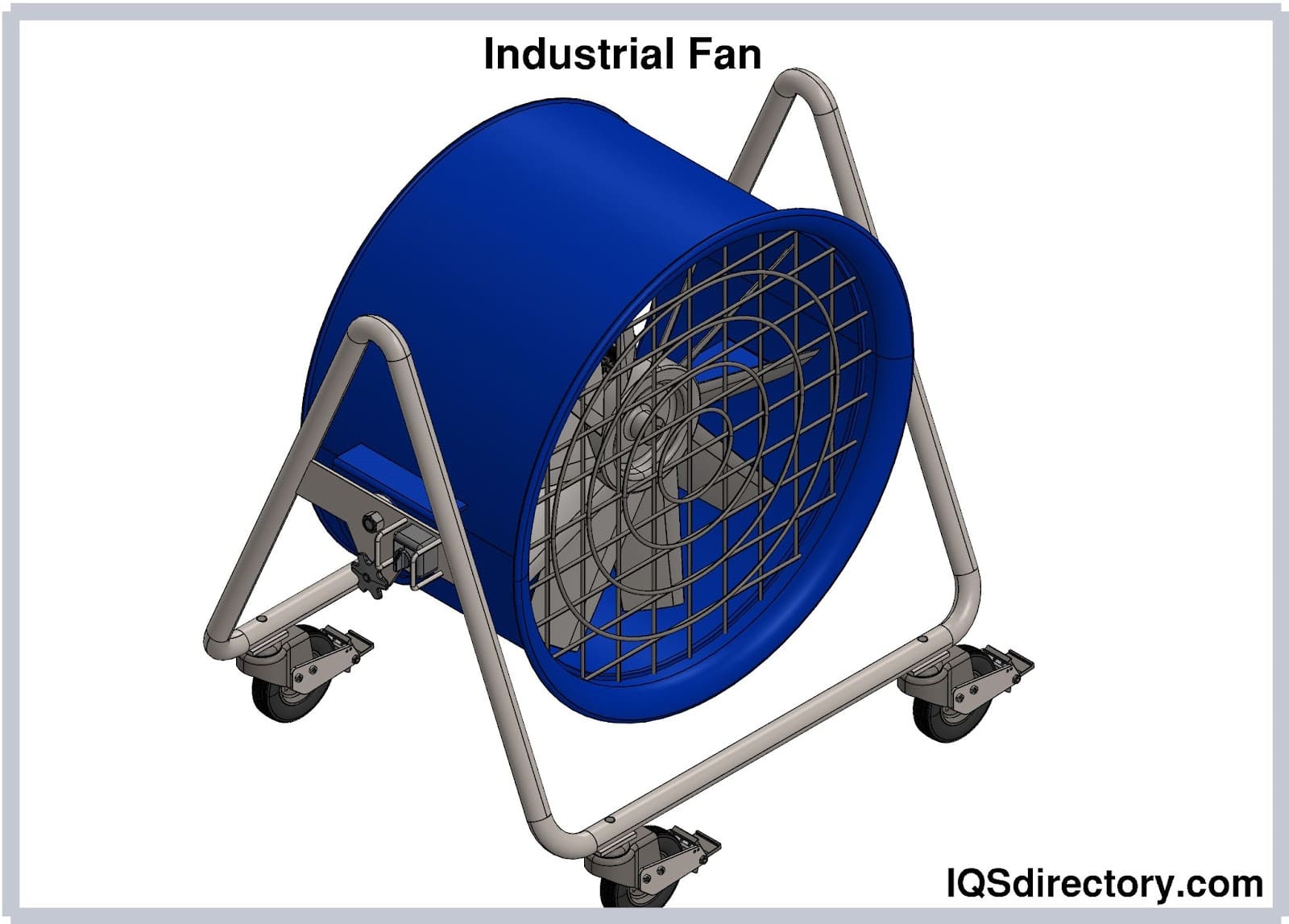

A blower fan is a device that efficiently and effectively enhances the flow of air within a workspace by making use of an impeller, airfoils (blades), and an electric motor. The main use of blower fans is as a permanent addition that increases airflow in a workspace and eliminates dirt, dust, and particulate matter. Blower fans are highly designed. Typically, they employ an electric motor to produce very high pressure in order to move a larger volume of air more quickly.

Blower fans can be categorized as axial, centrifugal, or positive displacement. The centrifugal blower fans consist of a gear system. Centrifugal blowers can also have multiple or single-stage construction. On the other hand, axial blower fans are much simpler and they consist of blades in a central shaft. Lastly, positive blower fans consist of a rotor geometry.

How Blower Fans are Made

Blower fans are required to be both durable and provide endurance through their function. They must create a great amount of force and pressure and, as a result, there is a need to manufacture them from sturdy and high-strength materials. They are made after considering the following factors provided below:

Flow Rate

The flow rate, which is a measure of airflow, is the first thing to note before determining the kind of blower fan required. Blower fans are capable of handling the same amount of gas and air despite their different densities. However, there is a need to understand the speeds required to carry these materials through the line.

Pressure Rating

The resistance to airflow is known as static pressure. It is usually caused by the air moving through ducting filters, hoses or pipes. Temperature and altitude have a direct effect on pressure and can affect blower fan performance. As a result, this issue has to be considered since it plays an important role in determining the quality of gas and air movement provided by blower fans.

Motor

A blower fan motor can be categorized as being either “belt drive” or “direct drive” motors based on how their fan and motor interact; each type has their advantages based on various factors. The environment where the blower is to function has to be examined because there are a variety of available motors for different conditions. When not exposed, they can be closed completely. Blower fans can make use of several motors such as induction, brushed, switched reluctance, and brushless. However, induction motors are mostly preferred since they generate greater power.

Impeller and Fan Blades

An impeller is the central part of any blower fan. Its rotation pulls air into the blower and increases its velocity; it also has the ability to change the direction of airflow. Fan blades are attached to impellers in a motor. Both the impeller selected and the number of blades used may greatly affect the flow rate.

Mount or Port Design

Blower fans may be configured using either a mount or a port design. In a mount design blower fan, the fan is mounted directly to an outlet using a flange. In a port-design blower fan, the blower is connected to an existing tube, duct, or vent.

Bearings

Bearings are an essential element for blower fans. They are mechanical assemblies that essentially allow the blades to spin inside a blower fan. They need intense monitoring and examination. Higher velocities are likely to cause bearing problems. Careful selection of bearings reduces the time spent replacing the bearings of a blower fan.

Types of Blower Fans

The types of blower fans include:

Positive Displacement Industrial Blower

Using two parallel rotary pistons, a positive displacement blower moves gas or air into the stage from the top input port. These are fixed inside a structure known as a conveying chamber. The pistons allow gas or air to be transported from the top to the bottom by rotating in opposing directions. PD blowers and rotary air blowers are other names for positive displacement blowers.

Positive displacement blowers can be found in two types:

Lobe Positive Displacement Blower

From the input to the discharge point, a positive displacement lobe blower transports a volume of gas that is essentially constant. It adheres to the external compression, or isochoric compression, concept.

To accomplish the necessary pressure increase, the medium (gas or air) is driven from an atmospheric state into a system with a certain resistance (back pressure). Lobe positive displacement blowers are not regarded as compressors because of this. The design of the machine's shell and spinning components controls how much gas it can manage.

Screw Positive Displacement Blower

The rotors of a screw positive displacement blower rotate in opposing directions while being precisely timed to preserve alignment. A series of working chambers are created between the rotors and the casing wall when the rotors mesh.

Between the rotors, the casing (radially), and the cover, the gas is suctioned from the intake side (axially). The air or gas is subsequently compressed while being transferred to the compression side (discharge). Here, the working chamber contracts. Internal compression produces a constant, uninterrupted flow of air. This reduces vibration and maintenance to extend the blower's lifespan.

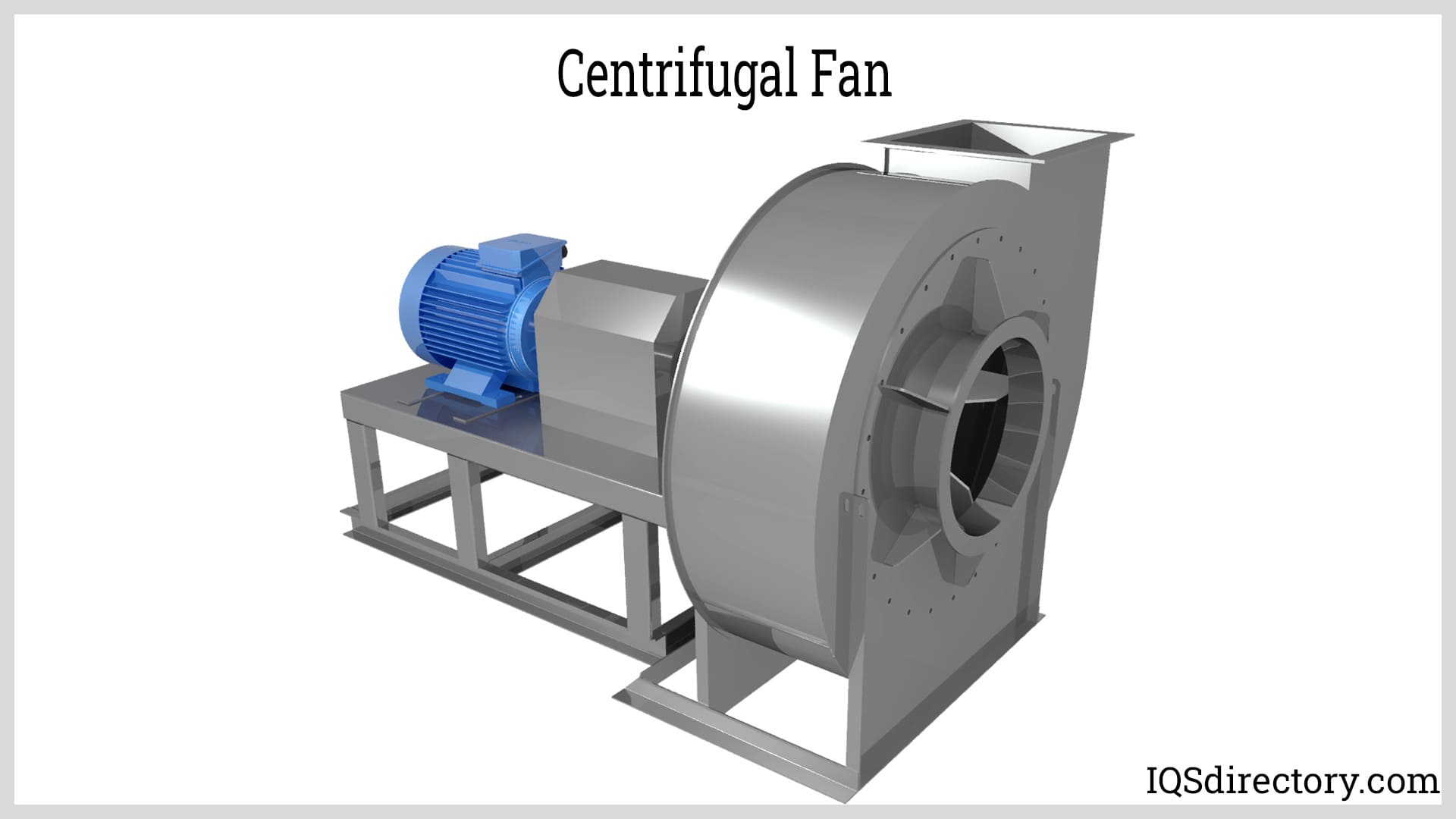

Centrifugal Blower

Centrifugal blower fans consist of a gear system. Centrifugal blowers can also have multiple or single-stage construction. Air enters through rotating impellers and its volume and velocity are increased until the blades force it out.

Regenerative Blower

Regenerative blower fans produce a continuous airflow that has low pressure. Regenerative blowers, also known as ring compressors, use impeller blades to draw air into the input port of the blower. The air is then accelerated outward and forward by the blower. The blower can be single or two stages. However, the two-stage type forms a higher pressure. These blowers provide large amounts of air to a particular spot using a pipe or hose. Compared to positive displacement blowers, they operate at lower pressures or vacuum levels, which lessens noise and vibration. These blowers are put into systems to supply vacuum and pressure for pneumatic conveying, aeration in fish farms and wastewater treatment facilities, as well as in applications which monitor air quality.

Axial Blower

An axial blower is characterized by the creation of negative and positive pressure around the blades in order to create airflow. The blades are placed vertically and tilted for changes in atmospheric pressure. The number of blades employed largely determines its performance.

There are other types of blower fans that are also used in various industrial sectors such as the vapor recovery industrial blower, helical screw industrial blower, and the high-speed industrial blower.

Applications

Blower fans are used in many industries and they have been of great importance. Their role is widely seen in the following:

- Fume extraction

- Dust removal

- Air handling

- Material handling

- Humidity maintenance

- Exhaust control

- Temperature control

Benefits

Blower fans provide a lot of advantages. They are a reliable way to lower operating costs. They reduce humidity levels so employees don’t feel sluggish. By reducing humidity levels, electronic devices are subjected less to corrosive influences. Additionally, they provide protection for both certain steps in production processes (painting) and, often, the items being produced themselves (food production). Most notably, they create healthier working conditions by collecting dust and other harmful particles so staff spend less time out, and companies pay less out, due to the removal of these harmful respiratory irritants.

Choosing the Right Blower Fans Manufacturer

To make sure you have the most constructive outcome when purchasing Blower Fans from a Blower Fans Supplier, it is important to compare at least 5 or 6 Manufacturers using our list of Blower Fans suppliers. Each Blower Fans Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Blower Fans business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Blower Fans companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services