Industrial fans are motorized devices that produce a large flow of air by rotating their blades. This airflow is done by the motor or turbine turning several blades attached to a hub and shaft. Industrial fans can be used for various purposes, such as cooling big commercial buildings and technical production lines. In addition, air circulation and flow are essential for worker health and application efficiency, regardless of workplace size. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

At DeKalb Blower, we specialize in the design and manufacturing of high-quality blowers that deliver exceptional performance and reliability. Our expertise lies in providing advanced airflow solutions tailored to meet the unique needs of diverse industries. By combining innovative engineering with precision craftsmanship, we create blowers that excel in efficiency, durability, and functionality.

Since 1959, Northern Blower® has offered a wide range of industrial blowers and fans including centrifugal fans, axial fans, swingout fans and custom made fans. Contact us today for information on our quality fans, blowers and equipment. We are committed to the manufacture of a rugged, long-lasting product delivered on time, every time. AMCA Member and ISO 9001:2000 Registered.

More Industrial Fan Manufacturers

Comprehensive Guide to Industrial Fans: Types, Applications, and Buyer Considerations

Industrial fans are crucial components across a wide range of commercial and industrial environments, providing robust ventilation, air movement, cooling, and exhaust solutions. Whether you are looking to enhance air quality, manage temperature, or control industrial processes, choosing the right industrial fan is essential to the safety, efficiency, and productivity of your operations. In this detailed guide, we explore the various types of industrial fans, their common applications, benefits, and key purchasing considerations to help plant managers, facility engineers, and procurement specialists make informed decisions when sourcing industrial fans from leading manufacturers.

Types of Industrial Fans

Industrial fans come in a diverse array of designs and configurations, each engineered to address specific airflow, pressure, and application requirements. Understanding the distinctions between different fan types is key to optimizing performance, energy efficiency, and long-term reliability.

Inline Duct Fans

Inline duct fans are powerful ventilation solutions designed to efficiently remove heat, humidity, fumes, and airborne contaminants from enclosed spaces such as grow rooms, industrial workshops, and large commercial buildings. Utilizing an electrically commutated (EC) motor, these fans ensure high efficiency and lower energy consumption, making them ideal for continuous operation in demanding environments. Their mixed flow impeller design enables operation in areas with high static pressure, while also minimizing noise levels—a critical factor for maintaining a comfortable workspace. Inline duct fans are typically installed along extensive duct runs and are often paired with flexible tubing, silencers, and carbon filters to further enhance air quality and system performance. If you’re seeking solutions for effective air extraction or HVAC support, explore inline duct fan options tailored to your facility’s requirements.

Forward Curved Fans / Squirrel Cage Fans

Also known as squirrel cage fans, forward curved fans are widely used in low to medium static pressure applications such as residential and light commercial HVAC systems, air handlers, and ventilation units. Their unique impeller design converts high-velocity air into a stable, directed airflow, making them suitable for environments where consistent air movement and quiet operation are essential. These fans often feature scroll, volute, or sirocco housing designs, enhancing efficiency and optimizing airflow patterns. If you’re comparing centrifugal fan styles, consider the specific benefits of forward curved fans for applications requiring low noise and moderate airflow. Compare forward-curved blower manufacturers or request technical specifications for your next project.

Variable Pitch Fans

Variable pitch industrial fans, typically a subset of axial fans, feature adjustable impeller blades that can be modified even while the rotor is spinning. This functionality allows operators to dynamically adapt airflow and pressure output in response to varying process demands or environmental conditions. Available in single-stage and double-stage models, variable pitch fans are commonly implemented in high-performance industrial settings such as power plants, mining operations, and complex ventilation systems where flexibility and precise control are paramount. The mechanical components—including hub springs, diaphragms, rotary air joints, and valve positioners—enable seamless pitch adjustments, optimizing efficiency and extending equipment lifespan. Are you looking for customizable airflow solutions? Browse variable pitch axial fan manufacturers to find the right fit for your application.

Industrial Cooling Fans

Engineered for durability and reliability, industrial cooling fans are constructed from high-strength, corrosion-resistant materials capable of withstanding harsh operating conditions. These fans play a vital role in maintaining safe temperatures for both personnel and sensitive equipment across manufacturing plants, warehouses, and large-scale distribution centers. By providing high air volume at low speeds, they deliver consistent, gentle cooling that minimizes heat stress without generating excessive noise or turbulence. Common use cases include spot cooling on production lines, general air circulation in expansive facilities, and supporting thermal management for heavy machinery. If you’re planning to improve workplace comfort or need to protect industrial assets from overheating, explore available industrial cooling fan solutions and learn how these products can enhance operational safety and productivity.

Paddle Wheel Fans

Paddle wheel fans are a robust choice for material handling, heavy-duty ventilation, and high-temperature exhaust applications. Their compact housing and heavy, deep radial blades make them highly effective for transporting airstreams containing dust, particulates, or abrasive media. The perpendicular blade arrangement allows for efficient movement of dense materials and ensures that the fan maintains performance even under extreme conditions. These fans are often used in industrial kilns, drying systems, and process exhausts where reliability, resistance to clogging, and ease of maintenance are critical considerations.

Radial Tipped Fans

Radial tipped fans are engineered to excel in high-volume, moderate- to high-pressure applications where efficiency and cleanliness are paramount. The rapid movement of air and particulates prevents the buildup of dust or debris on the impeller, reducing maintenance downtime and supporting continuous operation. These fans are frequently found in conjunction with cyclones, scrubbers, and baghouse dust collectors, making them a popular choice for industrial air pollution control, material conveying, and dust extraction systems.

Key Applications of Industrial Fans

Industrial fans are integral to a variety of sectors, ensuring optimal air movement, ventilation, and environmental control. Here are some of the most common and mission-critical applications:

- Gymnasiums and Athletic Facilities: Since physical activity takes place on equipment or flooring, most gyms have limited floor space to accommodate fans on their floors. As a result, gymnasium industrial fans are wall mounted, giving them more flexibility and the ability to fit the gym's layout. They are positioned carefully to provide adequate circulation in the available space, ensuring athletes stay comfortable during intense activity. The size of the room is a crucial consideration when installing an industrial fan in a gym; typically, several small-volume fans are used to optimize airflow. Looking to improve ventilation in a fitness center or sports complex? Consider industrial fans tailored for gyms and athletic spaces.

- Chemical Industry: Chemical industry operations involve the handling and use of potentially dangerous and explosive products and substances, which call for appropriate and secure storage. Sufficient and proper ventilation, provided by specially made industrial fans, is a crucial component of their storage. Industrial fans are strategically placed to keep chemicals cold and prevent the development of dangerous vapors, ensuring compliance with safety and environmental regulations.

- Oil and Gas Industry: Industrial fans for the oil and gas sector are built to function under the most demanding circumstances. They have welded flanges and components that resist corrosion, abrasion, moisture, and other potentially hazardous atmospheric elements. They are built of incredibly robust materials. Oil and gas industry fans go through a coating procedure for added protection, and are often designed for hazardous (ATEX) environments.

- Cement Manufacturing: Various processing fans that can work in high-temperature applications and resist abrasion and dust accumulation are needed for cement manufacturing. Pre-heater exhaust, kiln-induced draft, raw mill exhaust, cooler, forced draft, and mill exhaust fans are used in the cement industry to manage airflows and control emissions. Each fan type is selected based on its ability to withstand particulate-laden air and elevated temperatures.

- Power Generation: The forced draft, induced draft, and dust control fans used in the power generation industry must operate at extremely high temperatures. Therefore, heat-resistant paints and coatings are applied during the construction of power generation industry fans, and special bearings are also used. In addition, such fans are built with self-cleaning impellers due to the particulate level in the air stream from power-producing plants. These robust solutions are essential for boiler ventilation, emissions control, and turbine cooling.

- Food and Beverage Processing: Maintaining strict hygiene and air quality standards is crucial in the food sector. Industrial fans are used for exhaust, odor control, drying, and temperature management in food production and packaging facilities. Fans with easy-to-clean surfaces and corrosion-resistant materials help meet regulatory requirements.

- Pharmaceutical Manufacturing: Cleanroom environments and contamination control are top priorities in pharmaceutical plants. Specialized HEPA-filtered fans and laminar flow units are employed for air purification, temperature control, and dust containment..

- Mining and Heavy Industry: In underground mines and heavy manufacturing, rugged industrial fans are vital for ventilation, removal of toxic gases, dust suppression, and cooling of high-temperature equipment. Selecting explosion-proof and high-capacity fans is essential for safety and regulatory compliance.

- Warehousing and Logistics: Air circulation, temperature regulation, and condensation prevention are major concerns in warehouses and logistics hubs. High-volume, low-speed (HVLS) fans are commonly used to create consistent airflow, improving comfort and reducing energy costs.

Benefits of Industrial Fans

Investing in high-quality industrial fans delivers a wide range of operational and financial benefits, including:

- Improved Air Quality: Effective removal of dust, fumes, and airborne contaminants promotes a healthier, safer work environment and supports regulatory compliance.

- Thermal Management: Consistent cooling prevents overheating of equipment, reduces the risk of system failures, and protects worker health in hot climates or heat-intensive processes.

- Energy Efficiency: Advanced fan designs, such as EC motors and variable pitch mechanisms, reduce power consumption and operational costs through optimized performance.

- Enhanced Productivity: Maintaining optimal temperature and air quality increases comfort, concentration, and productivity among employees.

- Versatility: Industrial fans are available in a multitude of configurations, including centrifugal, axial, inline, and specialty designs, making them suitable for virtually any facility layout or process requirement.

- Custom Engineering: Many industrial fan manufacturers offer tailored solutions for unique challenges, including hazardous locations, corrosive environments, and high-pressure or high-temperature applications.

- Noise Reduction: Modern fans incorporate sound-attenuating features and accessories, creating a quieter and more comfortable working environment.

Industrial Fan Selection: Key Decision Factors

Choosing the optimal industrial fan for your facility involves careful consideration of technical specifications, project requirements, and long-term operational goals. Here are essential decision factors to guide your evaluation process:

- Airflow and Pressure Requirements: Calculate the required cubic feet per minute (CFM) and static pressure based on facility size, process needs, and environmental conditions.

- Application Environment: Assess exposure to heat, moisture, chemicals, or dust to determine the appropriate fan material, coating, and enclosure rating (such as NEMA or IP protection).

- Fan Type and Configuration: Decide between centrifugal, axial, inline, or specialty fan types based on your space constraints and process demands.

- Energy Efficiency: Evaluate options featuring energy-efficient motors, variable speed drives, and advanced control systems to maximize cost savings.

- Noise Levels: Consider sound attenuation and vibration isolation for environments where noise control is a priority.

- Maintenance and Accessibility: Look for fans with easy-access service points, self-cleaning features, and robust construction for reduced maintenance and downtime.

- Compliance and Certifications: Ensure the fan meets industry standards, such as OSHA, AMCA, or ATEX, especially for hazardous or regulated environments.

- Budget and Lifecycle Costs: Balance initial purchase price with operational efficiency, expected lifespan, and total cost of ownership.

How to Choose the Right Industrial Fans Manufacturer

To ensure a successful purchase and long-term satisfaction, it is important to compare multiple industrial fan manufacturers and suppliers. Here’s how to streamline your decision process:

- Research and Compare: Evaluate at least five reputable manufacturers using our curated list of industrial fan companies. Assess their experience, specialization, and track record in your application sector.

- Review Business Profiles: Visit each manufacturer’s business profile page to understand their core competencies, engineering capabilities, and product range. Many profiles include case studies, testimonials, and technical resources.

- Request Custom Quotes: Use the integrated contact form to directly communicate with manufacturers, request product catalogs, or obtain a tailored quotation based on your project specifications.

- Preview Websites: Our patented website previewer allows you to quickly scan each company’s offerings without leaving the directory, saving time in your research.

- Submit an RFQ: Utilize our simple Request for Quote (RFQ) form to contact multiple suppliers simultaneously. This helps you compare pricing, lead times, and support for your specific requirements.

Looking for expert advice or technical support? Contact our industrial fan specialists for detailed guidance on selecting, installing, and maintaining your ventilation solutions.

Frequently Asked Questions About Industrial Fans

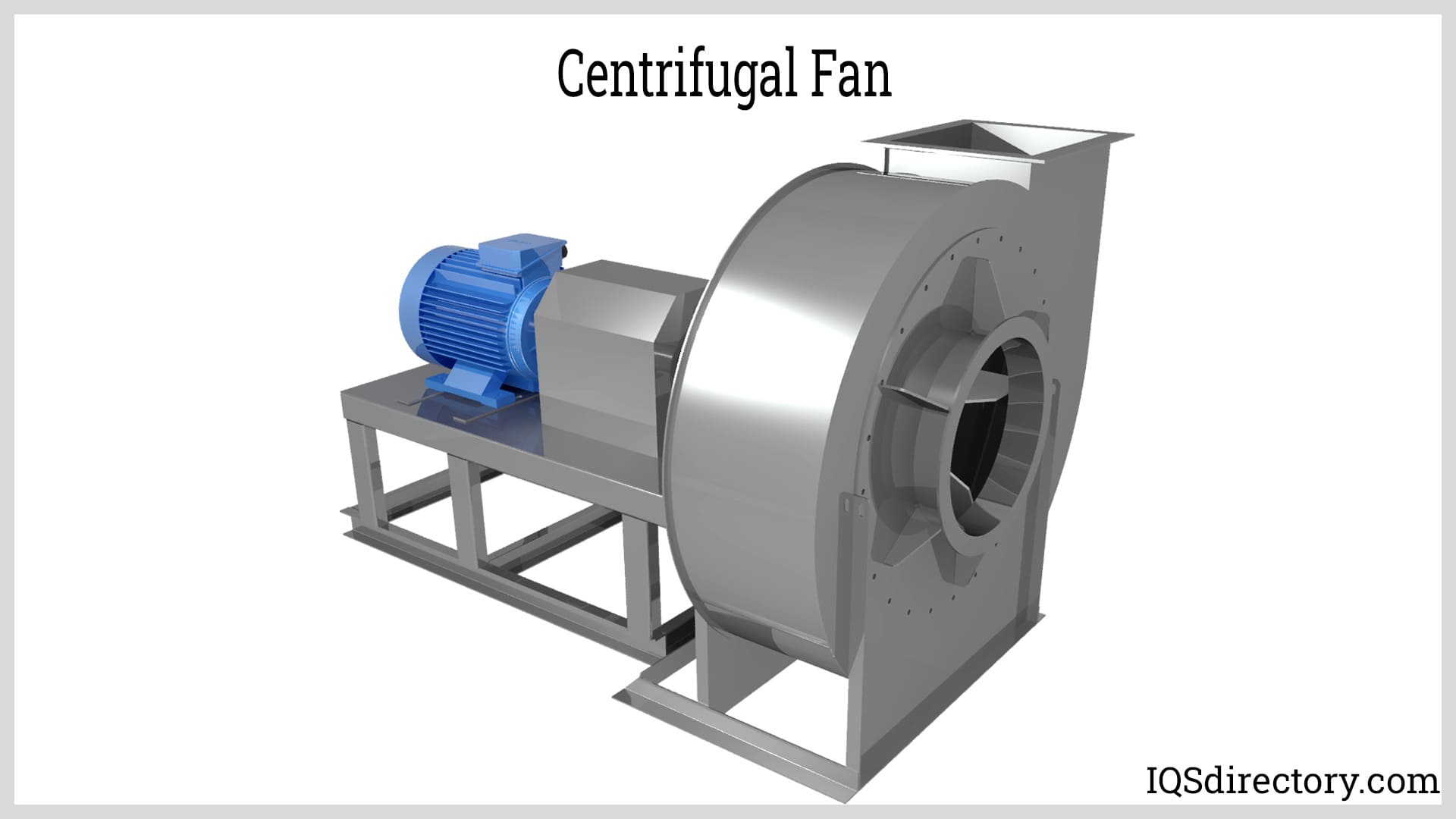

- What is the difference between centrifugal and axial industrial fans?

Centrifugal fans use a rotating impeller to increase air velocity and pressure perpendicular to the fan’s intake, ideal for high-pressure applications and ducted systems. Axial fans move air parallel to the shaft, providing high airflow at low pressure, suitable for general ventilation and cooling large open spaces. - How do I determine the correct fan size for my facility?

Calculate the total air volume (in cubic feet or meters) of your space and determine the necessary air exchanges per hour based on your industry’s standards. Consulting with a fan manufacturer or HVAC engineer ensures accurate sizing for optimal performance. - What maintenance is required for industrial fans?

Routine maintenance includes cleaning blades and housings, checking bearings and motor alignment, inspecting for wear or corrosion, and verifying secure mounting. Scheduled preventive maintenance prolongs fan life and reduces unexpected downtime. - Are there energy-efficient options for industrial fans?

Yes, many modern industrial fans utilize EC (electronically commutated) motors, variable speed drives, and aerodynamic blade designs to maximize energy savings. Selecting the right control system can further reduce operating costs. - Can industrial fans be customized for hazardous environments?

Absolutely. Many manufacturers offer explosion-proof, corrosion-resistant, and ATEX-compliant industrial fans designed for hazardous or regulated locations. Specify your requirements when requesting a quote to ensure proper certification. - How do I reduce noise from industrial fans?

Employ sound attenuators, vibration isolators, and select fans with low-noise impeller designs. Proper installation and maintenance are also key to minimizing operational noise.

Get Started: Sourcing the Best Industrial Fans for Your Application

Ready to find the ideal industrial fan for your facility? Whether you’re upgrading an existing system, tackling new construction, or seeking solutions for a specialized application, our industrial fan directory connects you with top-rated manufacturers and suppliers who can meet your technical, regulatory, and budgetary needs.

- Request quotes directly from multiple vendors for competitive pricing and lead times.

- Consult with engineering experts for custom designs or unique environmental challenges.

- Access detailed product specifications, case studies, and industry best practices to inform your decision.

Don’t see your specific application or have additional questions? Contact us today for personalized support and recommendations.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services