A centrifugal fan is defined as an air-moving device that consists of an impeller for pulling air into a tube-shaped structure and later forces it rapidly outward at an angle. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

At DeKalb Blower, we specialize in the design and manufacturing of high-quality blowers that deliver exceptional performance and reliability. Our expertise lies in providing advanced airflow solutions tailored to meet the unique needs of diverse industries. By combining innovative engineering with precision craftsmanship, we create blowers that excel in efficiency, durability, and functionality.

Since 1959, Northern Blower® has offered a wide range of industrial blowers and fans including centrifugal fans, axial fans, swingout fans and custom made fans. Contact us today for information on our quality fans, blowers and equipment. We are committed to the manufacture of a rugged, long-lasting product delivered on time, every time. AMCA Member and ISO 9001:2000 Registered.

More Centrifugal Fan Manufacturers

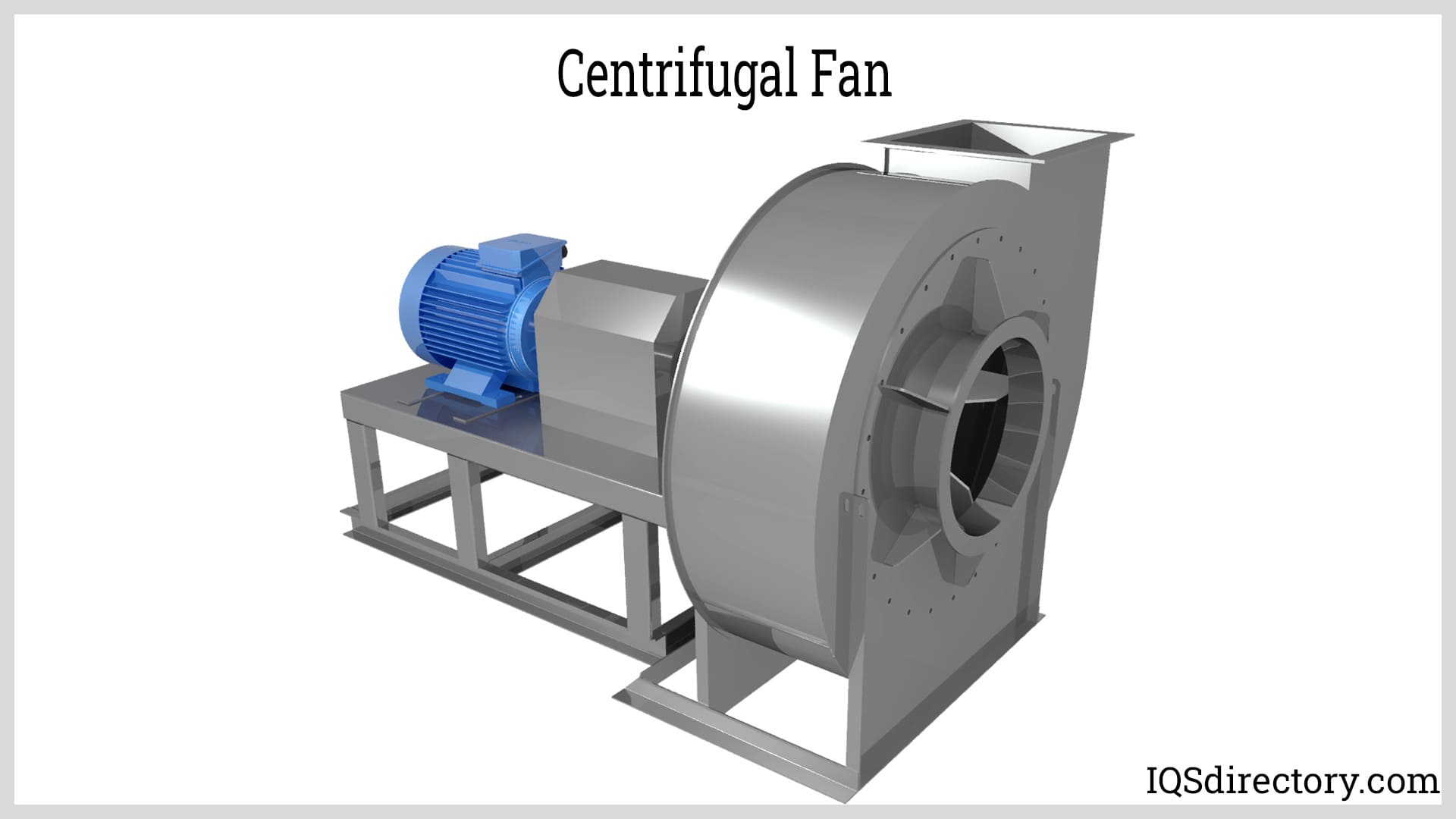

What is a Centrifugal Fan?

A centrifugal fan is defined as an air-moving device that consists of an impeller for pulling air into a tube-shaped structure and later forces it rapidly outward at an angle. Essentially, centrifugal fans take in air (or another gas) and maximize its velocity outward.

How Centrifugal Fans Work

A mechanical device known as a centrifugal fan employs rotational force to produce airflow. They have a very simple structure and design which has provided their name. The fan is often attached to an electric motor and has a number of uses, including cooling, ventilation, and circulation applications.

The impeller has blades within the blower that are in connection to a hub.The angle of the blades usually determines the effectiveness and efficiency of how fast the air moves in the system. Although manual and automated controls are also available for centrifugal fans, most centrifugal fans utilize a motor to turn the fan’s blades in order to produce a windflow.

Centrifugal fans achieve this by pulling the air (or other gas) inwards through blades moving at a very high rate and then forcing it outward through a series of ducts and tubes where it is pressurized to produce increased flow. The direction of airflow is parallel to the hub position. The centrifugal fan structure does not need housing although most common designs contain housing for protection.

It is typical to utilize a curved blade, such as an arc of the same thickness, in order to have an appropriate velocity distribution over the surface of the blade. In order to strengthen the impeller and decrease gas or air leakage between the blades and the casing, the impeller often features a cover disc. The cover and blade are joined together by welding or riveting. The welded impeller has a smooth flow path and is lightweight. Small centrifugal fans with low and medium pressures also may have cast aluminum alloy impellers.

Types of Centrifugal Fans

Centrifugal fans come in the following types:

Airfoil Centrifugal Fans

Airfoil centrifugal fans have high airflow volume. They have lower power consumption characteristics. They also consist of a leading edge. Their unique design of the airfoil blades makes them able to handle volumes of air to moderate static pressure. These fans can run at a high speed and they have great efficiency as compared to inclined blower.

Backward Inclined Centrifugal Fans

Backward inclined centrifugal fans consist of three different blade designs. These blade designs are curved airfoil, curved single-thickness, and flat single-thickness blades. Despite differences in their blade design, they are larger and heavier as compared to curved forward fans and their direction of motion is also in opposite directions.

Curved Airfoil Blade

These are used in applications that have low pressure and require high volume airflow. They are mostly used for cleaning moving gasses or air with tiny amounts of erosive substances.

Curved Single-Thickness Blade

These blades are capable of moving gasses and air that have very high temperatures and minimum corrosive materials. They consist of hard surfaces and liners for extra protection.

Flat Single-Thickness Blade

These are very efficient, strong, and cost-effective as compared to backward curved designs.

Forward Curved Centrifugal Fans

They are also called squirrel cage fans. The reason is that the wheel of the fan is in the form of a squirrel cage wheel. Their structure is very fragile and is not suitable for industrial purposes. However, they are ideal for applications that require low pressure and low speeds like air conditioning units and domestic furnaces.

Inline Centrifugal Fans

They have a rugged construction that consists of a tube casing and a backward inclined wheel. They are mainly for square ducts where they act as clean air boosters for exhaust and supply systems. They can be installed in different levels at any angle.

Plug Fans

These are well known for their wide range of names. They are usually used in high-temperature applications, for dust collection, or in autoclave vessels. They are designed for specific extreme temperature uses.

Radial Centrifugal Fans

They are also known as paddle wheel fans. This is because their blades are attached to an impeller in a straight way and they have a remarkable resemblance to paddle wheel boat paddles. Again, the impeller, which is the set of blades inside a fan’s blower mechanism, revolves independently and directs the air flow. The air that it uses is typically drawn in from the sides of the fan and expelled via the outlet. Radial flat blades on the impeller accelerate the air when it strikes the fan wheel and spins at a right angle in radial fans. The term comes from the way the accelerated air is discharged—radially. The centrifugal force, which is created in a spinning column, causes the airflow. These fans might be powered by a motor or a belt.

Applications of Centrifugal Fans

Centrifugal fans are used in several industries and some of their uses are given below:

- Clean air handling

- Dust removal

- Pneumatic material handling

- Saturated air treatment

- High-temperature applications

- Dairy processing

- Incinerators

Benefits of Centrifugal Fans

Centrifugal fans are known for their reliability and endurance and, as a result, they are preferred over axial fans for many applications as a procedure of effectively moving air. Centrifugal fans have numerous benefits which include:

- They are maintenance-free and highly efficient.

- They can save a large amount of money, making them a lower-cost operation.

- Centrifugal fans prevent overloads due to the fact that they are made with enough horsepower to stop the motor from overloading.

- They can operate in airflow environments where they can be adjusted to meet different operational requirements.

- Centrifugal fans are durable.

- They are designed to function in toxic conditions, high temperature, corrosive, and high humidity environments

Choosing the Proper Centrifugal Fans Manufacturer

To make sure you have the most positive outcome when purchasing Centrifugal Fans from a Centrifugal Fans Company, it is important to compare at least 4 Manufacturers using our list of Centrifugal Fans companies. Each Centrifugal Fans Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Centrifugal Fans company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Centrifugal Fans businesses with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services