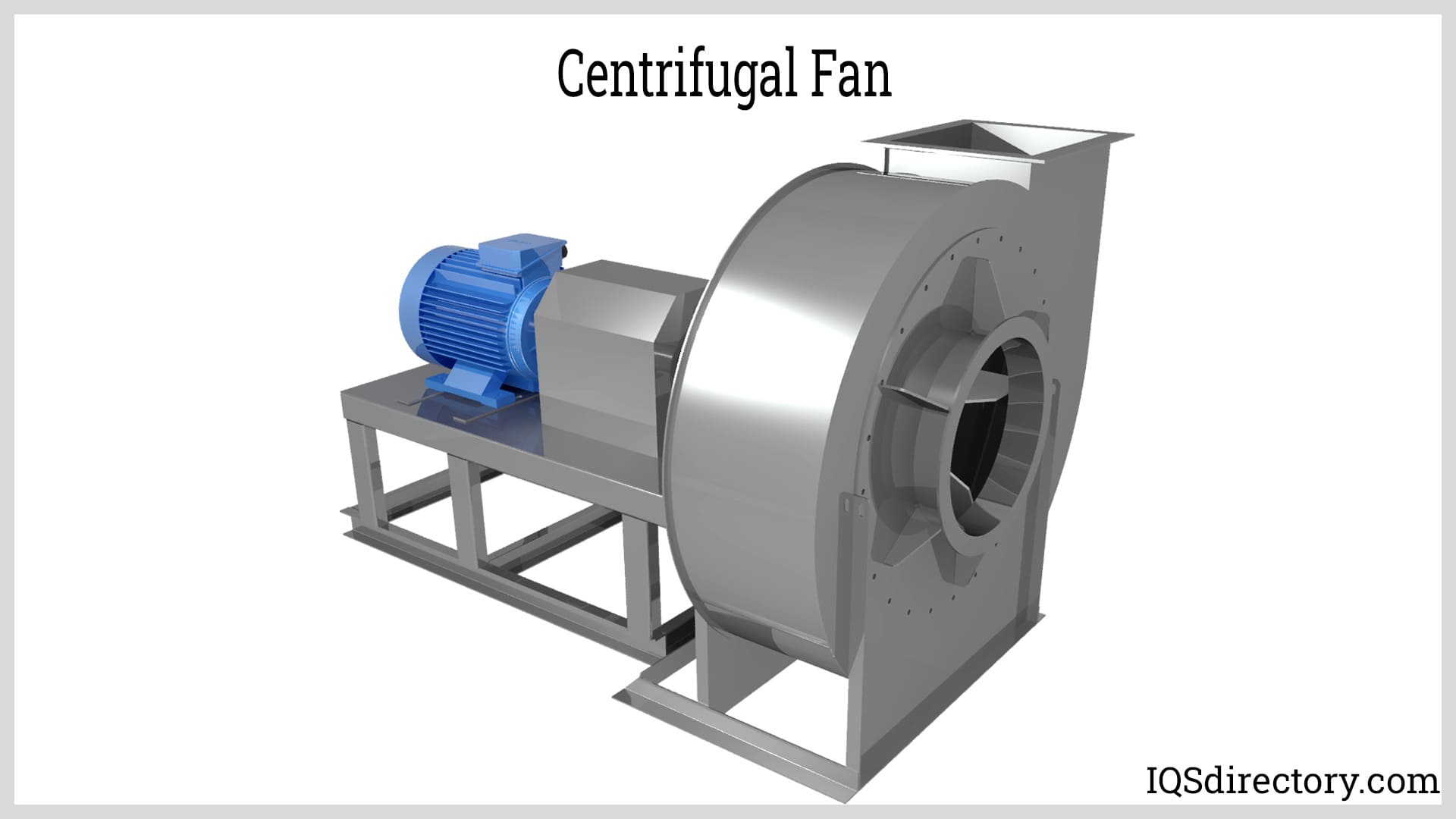

Multistage centrifugal exhausters are horizontal multiple-stage centrifugal compressors that use bearings, a shaft, and impellers to remove or separate air or gas. They have a tightly sealed body of carbon steel or iron that houses the impellers and shaft. Inlets and discharge heads are located at opposite ends of the body and have direct access to the set of impellers. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

At DeKalb Blower, we specialize in the design and manufacturing of high-quality blowers that deliver exceptional performance and reliability. Our expertise lies in providing advanced airflow solutions tailored to meet the unique needs of diverse industries. By combining innovative engineering with precision craftsmanship, we create blowers that excel in efficiency, durability, and functionality.

Since 1959, Northern Blower® has offered a wide range of industrial blowers and fans including centrifugal fans, axial fans, swingout fans and custom made fans. Contact us today for information on our quality fans, blowers and equipment. We are committed to the manufacture of a rugged, long-lasting product delivered on time, every time. AMCA Member and ISO 9001:2000 Registered.

More Multistage Exhauster Manufacturers

Although axial fans can exhaust contaminated air or gas, multistage exhausters are sturdier, more reliable, and more economical. Industrial complexes may have several exhausters for each piece of equipment or a single central exhauster, depending on the size of their operation.

Industries that produce toxic vapors, contaminants, and gasses rely on multistage exhausters to remove harmful substances to maintain clean and safe conditions. In addition, the exceptional durability of multistage exhausters makes them an ideal choice for separating and removing toxins.

Uses for Multistage Exhausters

Since their inception, multistage exhauster have become essential to multiple industries. For example, in the biogas industry, they are used to separate gas from sludge to produce biogas. Multistage exhausters' wide and varied use covers a wide spectrum of innovative and inventive methods for extracting, removing, and reusing gasses.

Food Production

Carbon dioxide (CO2) is used in the food industry to control insects and pests. In addition, using CO2 guarantees food processing quality and removes contamination concerns. At the end of food processing, the CO2 is collected instead of released into the atmosphere. Multistage exhausters are used to collect the CO2 such that it can be recycled and reused. The process reduces waste and increases efficiency.

Landfill Gas Extraction

Landfills are covered and compressed to create an anaerobic condition, a decomposition process. The anaerobic condition produces methane and carbon dioxide, which could be harmful if released into the air. Multistage exhausters extract the gas through a pipe connected to the landfill.

Aside from the obvious atmospheric factors, the United States government regulates the amount of gas that can be released into the air. Multistage exhausters reduce the remaining gas to a fraction of government standards.

Biogas Production

Biogas is produced by the thermochemical conversion of biomass. It is composed of methane, the same compound that makes up natural gas. The final product of biogas extraction can be used as natural gas. Therefore, biogas is referred to as renewable natural gas or biomethane. The process for the production of biogas begins with bacteria that break down biomass to produce biogas.

The extraction process for biogas is similar to that used in landfills. A multistage exhauster is attached by a pipe to the biomass and collects the methane produced by the bacterial breakdown. The collected methane with portions of carbon dioxide is then processed to produce renewable natural gas.

Components of a Multistage Exhauster

The structure of a multistage exhauster is similar to that of a multistage centrifugal blower. Both have impellers, a shaft, a motor, housing, inlets, and discharge heads. A multistage blower pulls in air or gas and places it under pressure before releasing it for further processing. A multistage exhauster pulls in air or gas and extracts portions to purify the air or collect materials.

Impellers

The main working part of a multistage exhauster is the impellers, similar to fans. Although there are several varieties of impellers, shrouded impellers are used the most due to their ability to withstand the extreme pressure of a working multistage exhauster. The impellers occupy the central part of a multistage exhauster. They draw in air or gas through the inlet and move the air or gas along to the outlet or discharge head.

Accurate placement of the impellers is essential to the smooth operation of a multistage exhauster. They must be positioned sufficiently to have clearance from the casing but close enough to the casing for efficient operation and movement of the air or gas.

Shaft

The impellers are connected to the shaft that runs the full length of the multistage exhauster from the inlet to the outlet and keeps the impellers aligned. The constant motion of the shaft requires that it be made of the most durable materials. In most cases, it is made of carbon steel or stainless steel.

Bearings

Both ends of the shaft are supported by self-aligning bearings mounted in a bearing housing and connected at one end to the motor. The bearings must be carefully maintained and lubricated to ensure proper performance.

Motor

Although there are various motors used to power multistage exhausters, most have an electric motor that is directly or indirectly driven by a belt. They operate at a constant speed of 3600 RPM with a squirrel cage design.

Housing or Casing

The housing encompasses the mechanism of a multistage exhauster and is made of cast iron, carbon steel, or aluminum. Each section of the housing is connected with high-strength steel rods. Aluminum housings are used for smaller multistage exhausters that do not have to endure stress or heavy wear.

Base

The complete multistage exhauster sits on a solid base of steel designed to prevent vibrations. The steel-framed base is supported by machined pads that ensure proper positioning and secure alignment. The base plate rests on a concrete foundation, not bolted or grouted to the floor.

Other components included in a multistage exhauster include a diffuser for guiding air or gas, flexible couplings, and baffle rings.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services