An air blower is a simple and efficient electrical component used in homes and businesses to remove dust and other unwanted bits of material. Air blowers force air to flow via a curved route and out of the blower by a dynamic pressure created by a rotor, or impeller, at the center of the device. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

At DeKalb Blower, we specialize in the design and manufacturing of high-quality blowers that deliver exceptional performance and reliability. Our expertise lies in providing advanced airflow solutions tailored to meet the unique needs of diverse industries. By combining innovative engineering with precision craftsmanship, we create blowers that excel in efficiency, durability, and functionality.

Since 1959, Northern Blower® has offered a wide range of industrial blowers and fans including centrifugal fans, axial fans, swingout fans and custom made fans. Contact us today for information on our quality fans, blowers and equipment. We are committed to the manufacture of a rugged, long-lasting product delivered on time, every time. AMCA Member and ISO 9001:2000 Registered.

More Air Blower Manufacturers

Types of Air Blowers

Air blowers, also known as industrial blowers or air movers, are essential mechanical devices designed to move air or gas for various industrial, commercial, and residential applications. Choosing the right type of air blower is crucial for optimizing airflow, energy efficiency, and overall system performance. Below, we explore the most common types of air blowers, their operational principles, and ideal use cases to help you make an informed decision when evaluating air blower solutions for your specific requirements.

Regenerative Air Blowers

High-flow, low-pressure compressed air blowers, commonly referred to as regenerative industrial blowers, are widely used for applications demanding continuous, non-pulsating airflow. Regenerative blowers utilize a unique "non-positive displacement" mechanism, enabling them to move large volumes of air at low pressures and medium flows. This design makes them ideal for scenarios where a vacuum or rapid transfer of compressed air at low pressure is needed, such as in pneumatic conveying, wastewater treatment aeration, and packaging machines.

Inside a regenerative blower, air moves throughout the housing, creating pressure due to a ring of space between the blades and the housing. Some air bypasses the first set of blades to interact with a second set, resulting in a compact yet highly efficient design capable of moving substantial air volumes. Regenerative blowers are available in single-stage and double-stage models. In a single-stage blower, air circulates once; in a double-stage blower, it passes through twice, producing higher pressure and greater operational versatility. When searching for low-maintenance, oil-free, and quiet air movement solutions, regenerative blowers are a leading choice.

Common Applications for Regenerative Air Blowers

- Pneumatic conveying systems for powders and granules

- Wastewater treatment aeration tanks and fish pond aeration

- Vacuum lifting and material handling systems

- Medical and laboratory vacuum systems

- Printing presses and paper handling equipment

Positive Displacement Air Blowers

Positive displacement air blowers, sometimes called rotary air blowers or Roots blowers, deliver high-pressure, low-flow performance by trapping and displacing air. Unlike regenerative blowers, positive displacement blowers employ counter-rotating rotors inside an expanding chamber. As the rotors turn, they draw air in, trap it, and convey it toward the outlet at a constant flow rate regardless of downstream pressure variations. This consistent operational flow makes positive displacement blowers highly effective for applications where stable pressure and reliability are critical.

These blowers are commonly used in bulk material handling, pneumatic conveying of dense materials, combustion air supply for industrial furnaces, wastewater aeration, and vacuum generation. Their robust construction and ability to handle varying pressures make them a popular choice for heavy-duty industrial processes.

Benefits of Positive Displacement Air Blowers

- Consistent airflow regardless of system pressure

- Reliable operation in harsh industrial environments

- Suitable for high-pressure air and gas applications

- Low maintenance and long service life

- Ideal for conveying abrasive or dense materials

Positive Displacement Air Blower Use Cases

- Pneumatic conveying of cement, grains, and plastics

- Supplying combustion air to burners and kilns

- Aeration for municipal and industrial water treatment

- Vacuum packaging and bottle filling lines

- Dust collection and bulk transfer systems

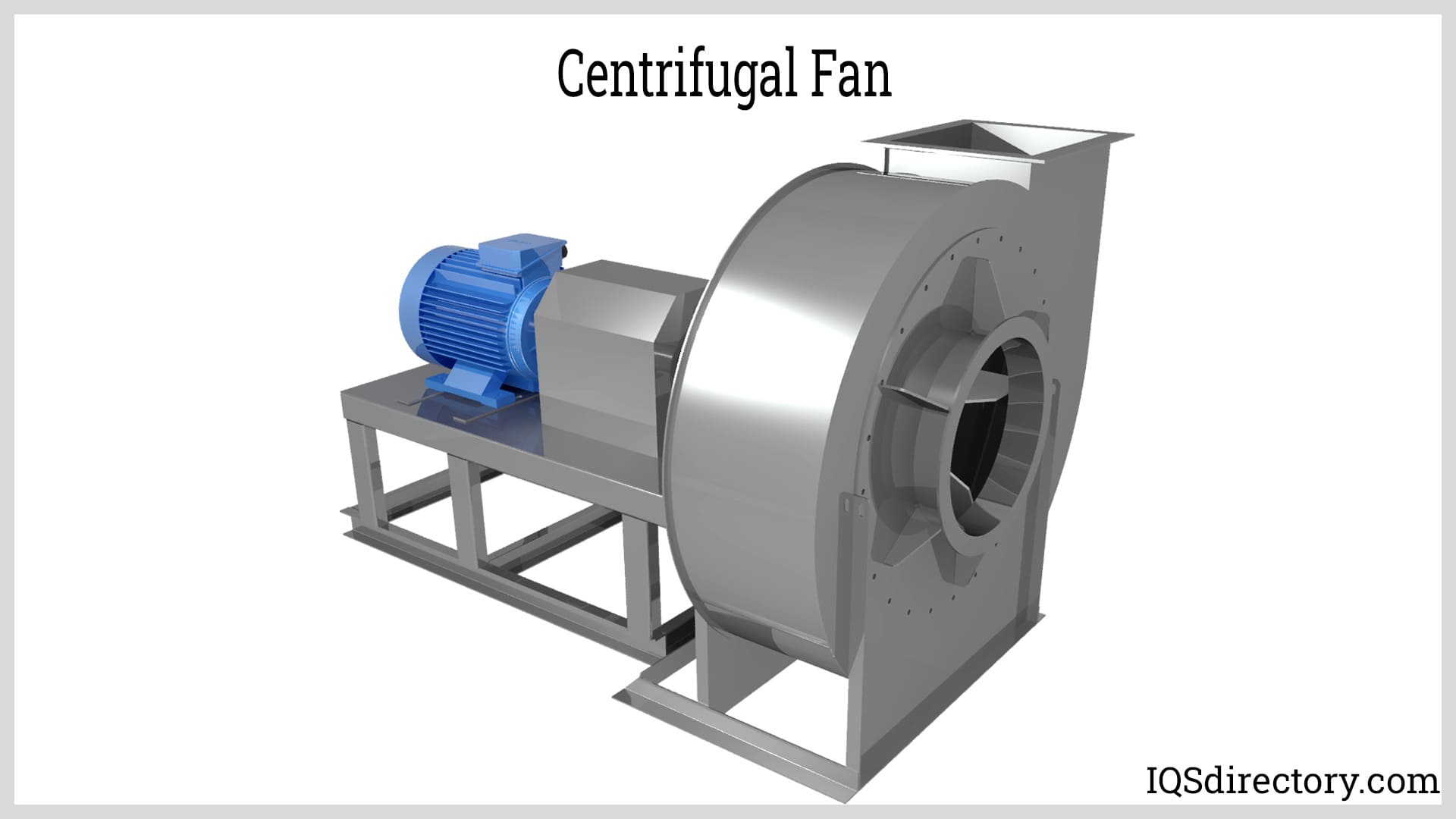

Centrifugal Air Blowers

Centrifugal blowers are impeller-based air movement devices designed for very low-pressure, high-volume airflow applications. Unlike positive displacement blowers, centrifugal blowers operate by accelerating air radially outward from the center of a rotating impeller, harnessing centrifugal force to generate continuous airflow. Output from a centrifugal blower varies with system pressure, making them a preferred choice for ventilation, cooling, dust collection, and HVAC applications where large volumes of air must be moved efficiently at relatively low pressures.

Centrifugal blowers are available in a variety of configurations—including forward-curved, backward-curved, and radial blade designs—to suit different system demands. Their quiet operation, ability to handle particulate-laden air, and compatibility with ducted systems make them a staple in commercial and industrial ventilation solutions.

Key Advantages of Centrifugal Blowers

- Efficient high-volume airflow for ventilation and cooling

- Adaptability to HVAC, dust collection, and filtration systems

- Available in corrosion- and spark-resistant models

- Low noise levels for indoor applications

- Can handle light particulate or contaminated air streams

Typical Centrifugal Blower Applications

- Industrial ventilation and air extraction

- Heating, ventilation, and air conditioning (HVAC)

- Boiler combustion air supply

- Fume and smoke removal systems

- Dust collection and air filtration units

Axial Industrial Air Blower

The airflow in an axial industrial blower is created from the positive and negative pressure found around its blades. The fan blades are positioned vertically and horizontally to account for variations in atmospheric pressure. An axial blower forces the air to travel in an axially-parallel direction to the shaft around which the rotating blades are mounted. The difference in air pressure produced by this design leads to continuous airflow. The quantity and form of an axial fan's blades affect its performance.

Axial blowers are highly efficient for moving large volumes of air over short distances, making them ideal for cooling, exhaust, and ventilation tasks in both industrial and commercial environments. Their streamlined construction and direct airflow path offer minimal resistance, reducing energy consumption while maximizing throughput. When selecting an axial fan or blower, consider blade design, noise level, and motor efficiency to match your application requirements.

Main Axial Blower Uses

- General industrial ventilation and exhaust

- Cooling for electrical enclosures and server rooms

- Tunnel and subway ventilation systems

- Drying rooms and process ovens

- Evaporative cooling and heat dissipation

High-Speed Industrial Air Blowers

High pressure and quick airflow are produced when a high-speed industrial blower is at work. Impellers are driven by an electric motor and positioned around the shaft to maximize the amount of air being absorbed in these blowers. A high-speed blower's architecture comprises a valve for air release and a compression unit for blower speed control; these elements can be changed to suit an operation's requirements.

High-speed air blowers are engineered for demanding industrial processes requiring rapid air movement and high static pressure. Their advanced motor and impeller designs support energy-efficient operation, precise speed control, and integration with automated process controls. These features make high-speed blowers indispensable for drying, pneumatic transport, and process cooling in manufacturing, food processing, and pharmaceutical industries.

High-Speed Blower Application Areas

- Rapid drying of surfaces, coatings, or electronics

- Material handling and pneumatic conveying systems

- Cleanroom air circulation and pressurization

- Industrial oven and furnace air supply

- Precision cooling in electronics manufacturing

Applications of Air Blowers

Air blowers are central to numerous industrial, commercial, and residential processes. Their versatility and efficiency make them indispensable for air movement, particulate removal, and supporting critical operations. Below is an expanded look at where air blowers play a vital role:

- Air Pollution Control: Industrial air blowers are used as a component of a larger system with an accompanying large-capacity filtering system used to eliminate chemicals, smoke, odors, and other pollutants from the air. These systems have up to 99% effectiveness to ensure that noxious odors, pollutants, and gas emissions are eliminated from a work environment. Looking for air quality improvement solutions in your facility? Explore how industrial air blowers can optimize your pollution control system.

- Paint Fume and Vapor Removal: Industrial blowers remove and filter paint fumes and vapors from small, enclosed workshops where they build up and pollute the air. Industrial exhaust blowers must be spark-resistant because some of the chemicals used in these applications may be combustible. Paint, lacquer, and varnish are all potential sources of combustion on their own and when applied to an object. Industrial air blowers provide the necessary air streams required to clear the airstream of these dangers and other harmful particulates both before and after pieces are painted. Pressure blowers are manufactured specifically to get the required pressure and drive needed to remove these particles. For these circumstances, spark-resistant blowers are often constructed with specially-designed aluminum impellers. In addition, industrial blowers have the force and strength to remove water vapor from cooling operations.

- Aquaculture and Water Treatment: The aquaculture business frequently uses air blower applications that call for compressed air or oxygen, whether it's to help ensure water quality, establish an effective feeding system, make a protective bubble curtain, or move live organisms from one location to another. Air blowers may be converted to generate oxygen in freshwater and saltwater applications. Considering improving your aquaculture system’s aeration? Compare regenerative blowers and positive displacement blowers for optimal water quality management.

- Home and DIY Applications: Air blowers may also be used at home for blowing away dust and debris. Handheld air blowers and compact air movers are popular for cleaning garages, patios, and workshops. Their portability and ease of use make them a favorite for homeowners and DIY enthusiasts.

- HVAC and Building Ventilation: Air blowers are fundamental components in heating, ventilation, and air conditioning (HVAC) systems, supporting air recirculation, exhaust, and temperature regulation in commercial buildings, hospitals, schools, and office complexes. How do you size an air blower for your HVAC system? Use our blower selection guide to match airflow requirements, static pressure, and energy efficiency ratings.

- Material Handling and Process Industry: In manufacturing, air blowers support pneumatic conveying, dust collection, drying, cooling, and combustion air supply. Their reliability and adaptability make them critical for process optimization and production line efficiency.

Factors to Consider When Selecting an Air Blower

When choosing an air blower for your application, it’s essential to evaluate several factors to ensure optimal performance, energy efficiency, and cost-effectiveness. Here are key considerations:

- Airflow Volume and Pressure: Determine the required cubic feet per minute (CFM) or cubic meters per hour (m3/h) and static pressure (inches of water gauge or Pascals) your system needs. This will guide your choice between high-flow centrifugal blowers or high-pressure positive displacement blowers.

- Ambient Environment: Consider temperature, humidity, and the presence of corrosive or combustible materials. Choose materials (e.g., stainless steel, aluminum, coated steel) and motor ratings suitable for your operating conditions.

- Noise Level: Noise-sensitive environments benefit from low-noise blower models, such as backward-curved centrifugal fans or insulated blower housings.

- Energy Efficiency: Look for blowers with energy-efficient motors, variable speed drives, and aerodynamic impeller designs to reduce operating costs.

- Maintenance Requirements: Select blower types and models that offer easy access for cleaning, bearing lubrication, and filter replacement, ensuring minimal downtime.

- Compliance and Safety: Ensure the blower meets relevant industry standards (e.g., ATEX, UL, CE) for hazardous locations or food-grade applications.

- Budget and Total Cost of Ownership: Factor in not only the initial purchase cost but also installation, energy usage, maintenance, and expected lifespan.

Need help choosing the right blower type? Try our interactive selection tool or contact a supplier for a custom recommendation based on your specifications.

Benefits of Air Blowers in Industrial and Commercial Applications

- Improved Air Quality: Effective removal of contaminants, dust, fumes, and odors leads to safer, healthier work environments.

- Enhanced Productivity: Reliable air movement supports continuous manufacturing, reduces downtime, and ensures consistent process performance.

- Energy Savings: Modern high-efficiency blowers lower electrical consumption, helping facilities meet green building standards and reduce operational costs.

- Versatile Integration: Air blowers are adaptable to diverse systems, including HVAC, material conveying, drying, and water treatment processes.

- Customization Options: Wide selection of sizes, materials, impeller types, and control features to match specific application needs.

- Compliance Support: Many industrial blowers are designed to meet environmental and safety regulations, supporting compliance for air quality and emissions control.

Choosing the Proper Air Blowers Supplier

To make sure you have the most constructive outcome when purchasing air blowers from an experienced supplier, it is important to compare at least 4 or 5 reputable companies using our Air Blowers directory. Each air blower manufacturer has a business profile page highlighting their areas of expertise, manufacturing capabilities, certifications, and a direct contact form for quote requests or technical support.

When evaluating suppliers, consider:

- Industry reputation and years of experience

- Range of blower types and customization services offered

- Availability of technical support and after-sales service

- Certifications for quality, safety, and environmental standards

- Lead times, shipping options, and global distribution capabilities

- Customer testimonials and project case studies

Review each air blower company’s website using our proprietary website previewer to get an idea of their specialties. Then, use our simple RFQ form to contact multiple companies with your requirements for competitive quotes. For complex projects, request a consultation or site visit to ensure your needs are fully understood and addressed.

Frequently Asked Questions About Air Blowers

What is the difference between a centrifugal blower and a positive displacement blower?

Centrifugal blowers use rotating impellers to move air at high volumes and low pressures. They are ideal for ventilation and general air movement. Positive displacement blowers trap and push air at higher pressures and lower volumes, making them suitable for pneumatic conveying and aeration systems.

How do I size an air blower for my industrial application?

Sizing an air blower requires knowing your required airflow (CFM or m3/h), static pressure, and environmental conditions. Use blower performance curves and consult with manufacturers or use selection tools for a precise match.

What maintenance is required for industrial air blowers?

Regular maintenance includes bearing lubrication, filter cleaning or replacement, inspection for wear and tear, and checking motor operation. Some blowers have oil-free designs for reduced maintenance needs.

Can I use an industrial air blower for dust collection?

Yes, many centrifugal and positive displacement blowers are designed for dust collection and filtration systems. Select a blower with appropriate airflow, pressure, and compatibility with particulate-laden air.

Where can I find reliable air blower suppliers and manufacturers?

Use our Air Blower Suppliers Directory to compare leading manufacturers, review product offerings, and request custom quotes.

Take the Next Step: Find Your Ideal Air Blower Solution

Whether you’re upgrading an existing system, specifying equipment for a new build, or seeking energy-efficient solutions for process optimization, selecting the right air blower is critical. Explore detailed product specifications, read application case studies, and connect with top-tier air blower manufacturers through our comprehensive directory. Ready to specify or buy an industrial air blower? Use our RFQ form to get competitive quotes tailored to your performance and budget requirements. For further guidance, consult our resources or reach out to our technical experts for personalized recommendations.

Maximize operational efficiency, ensure regulatory compliance, and create safer environments with the optimal air blower technology for your application.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services