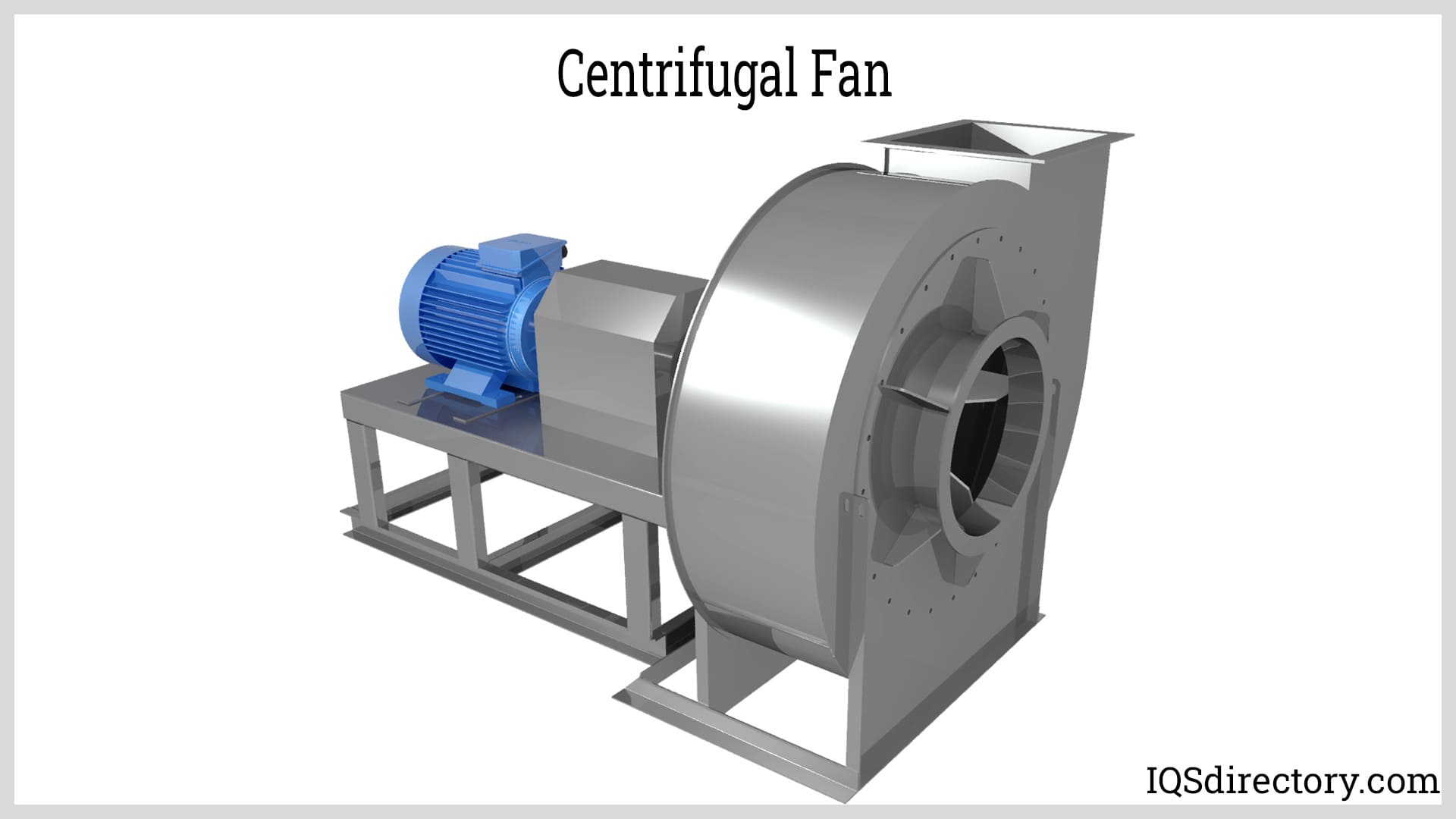

A centrifugal blower is an air-propelled motor or pump that moves air inside a blower and pushes it out at a 90-degree angle. Centrifugal blowers are the best for directing airflow through a duct and for spot cooling because they maximize static pressure. The motor and the impeller are this blower’s two main components. In contrast to a propeller, which forces out air, an impeller draws in air. Additionally, the centrifugal blowers lack a framework or an outside enclosure to provide some shielding. The advantage of blowers over fans is that they can achieve higher pressures of about 1.20 kg/cm2. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

At DeKalb Blower, we specialize in the design and manufacturing of high-quality blowers that deliver exceptional performance and reliability. Our expertise lies in providing advanced airflow solutions tailored to meet the unique needs of diverse industries. By combining innovative engineering with precision craftsmanship, we create blowers that excel in efficiency, durability, and functionality.

Since 1959, Northern Blower® has offered a wide range of industrial blowers and fans including centrifugal fans, axial fans, swingout fans and custom made fans. Contact us today for information on our quality fans, blowers and equipment. We are committed to the manufacture of a rugged, long-lasting product delivered on time, every time. AMCA Member and ISO 9001:2000 Registered.

More Centrifugal Blower Manufacturers

Additionally, they are employed in creating negative pressures for industrial vacuum systems. Centrifugal blowers resemble centrifugal pumps more so than centrifugal fans. Typically, the impeller is gear-driven and rotates at up to 15,000 rpm. Air is accelerated as it moves through each impeller in multi-stage blowers. Air is more efficient in single-stage blowers because it makes fewer rotations. Although they can have higher pressures, centrifugal blowers normally work at 0.35 to 0.70 kg/cm2 pressures. One feature is the tendency for airflow to decrease when system pressure rises rapidly, which can be problematic for material-conveying systems that rely on a constant air volume. They are, therefore, most frequently employed in applications resistant to clogging.

Working Principle of Centrifugal Blowers

The gas between the blades of the fan impeller spins with the motor when it drives the impeller to turn, expelling the gasses under the influence of centrifugal force. As the gas flow velocity rises, the kinetic energy in the flow is transformed into static pressure energy. The gas is then released through the exhaust port, creating a negative in the impeller because of the conversion of static pressure energy to velocity energy with an increase in fluid pressure. Since the outside gas is immediately introduced under the influence of atmospheric pressure and continually discharged and added under the influence of continuous impeller rotation, the continuous blast is achieved thanks to the negative pressure of the inlet. Wind pressure and air volume are often inversely proportional at the same power. Therefore, to maximize the motor's efficiency, a high wind pressure will result in a comparatively low wind volume under the same power. In contrast, a high wind volume will result in low wind pressure.

Types Of Centrifugal Blowers

Centrifugal fans and blowers typically have one of three wheels that suck air into the blower housing's inlet, past the wheel, and expel it through the housing's outlet at a 90-degree angle. Pressure and volume centrifugal blowers are the two most used varieties.

Pressure blowers are rated in static pressure water gauge (SPWG) and are intended to draw or push air at high pressures. Volume blowers have lower static pressures than pressure blowers and are made to draw or push bigger volumes of air, measured in cubic feet of air per minute (CFM).

Types Of Centrifugal Blower Wheels

One of three standard wheel types is employed by centrifugal blower fans:

- Forward curved

- Radial

- Backward curved

Forward Curved Wheels

The shallow blades of forward-curved centrifugal fans are typically pointed in the same direction as the spinning. Therefore, a forward-curved centrifugal fan works best in circumstances that require much air moving at slow speeds.

Forward-curved fans, often referred to as centrifugal forward-curved blowers, are frequently found in industrial settings, such as hospitals and huge commercial constructions. Their forward-curving wheels are how they got their name.

This kind of technology is tremendously helpful for huge HVAC systems and other uses.

Radial Blower Wheels

The type of wheel most frequently utilized in filthy surroundings is the radial-bladed wheel (Figure 4). The radial wheel is used in applications like material transportation and dusty environments because it can create static pressures of up to 40 inches. In addition, its ability to clean itself is a helpful characteristic.

Backward Curved Wheels

Backward curved (BC) model wheels are a third form of the common wheel (Figure 5). These wheels can operate at high static efficiency and create significant amounts of air at moderate pressures (5 to 20 inches of static pressure).

Applications Of Centrifugal Blower

- Clean Air Handling – Centrifugal fans are crucial when managing air in greater volumes.

- Manipulation of materials – Sand, plastic pellets, sawdust, wood chips, grain, paper trim, and many more particles can all be processed through material handling.

- Processes using high temperatures – Many processes rely on high-temperature or heating systems.

- Treatment of saturated air – Most centrifugal fans process saturated air regularly, and heavy-duty materials and moisture-resistant coatings are necessary for these applications.

- Operations involving dust loading – These fans are used in industrial processes as part of the dust collection system to maintain air quality.

Advantages Of Centrifugal Blowers

- Exceptional energy efficiency

- Enhanced robustness

- Capacity to prevent overloading

- Simple to maintain

- High adaptability

- Several sizes

Disadvantages Of Centrifugal Blowers

- Utilizes more power and energy than other models

- Higher market value

- Produces little air

Choosing the Right Centrifugal Blower Company

To make sure you have the most constructive outcome when purchasing Centrifugal Blower from a Centrifugal Blower Supplier, it is important to compare at least 4 Companies using our list of Centrifugal Blower companies. Each Centrifugal Blower Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Centrifugal Blower business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Centrifugal Blower companies with the same quote.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services