The efficient and precise movement of air and gasses is necessary for many industries and commercial services. This air or gas is often moved by a sturdy and dependable multistage centrifugal blower, which performs exceptionally well with little need for maintenance. Read More…

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications.

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal...

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in ...

At DeKalb Blower, we specialize in the design and manufacturing of high-quality blowers that deliver exceptional performance and reliability. Our expertise lies in providing advanced airflow solutions tailored to meet the unique needs of diverse industries. By combining innovative engineering with precision craftsmanship, we create blowers that excel in efficiency, durability, and functionality.

Since 1959, Northern Blower® has offered a wide range of industrial blowers and fans including centrifugal fans, axial fans, swingout fans and custom made fans. Contact us today for information on our quality fans, blowers and equipment. We are committed to the manufacture of a rugged, long-lasting product delivered on time, every time. AMCA Member and ISO 9001:2000 Registered.

More Multistage Blower Manufacturers

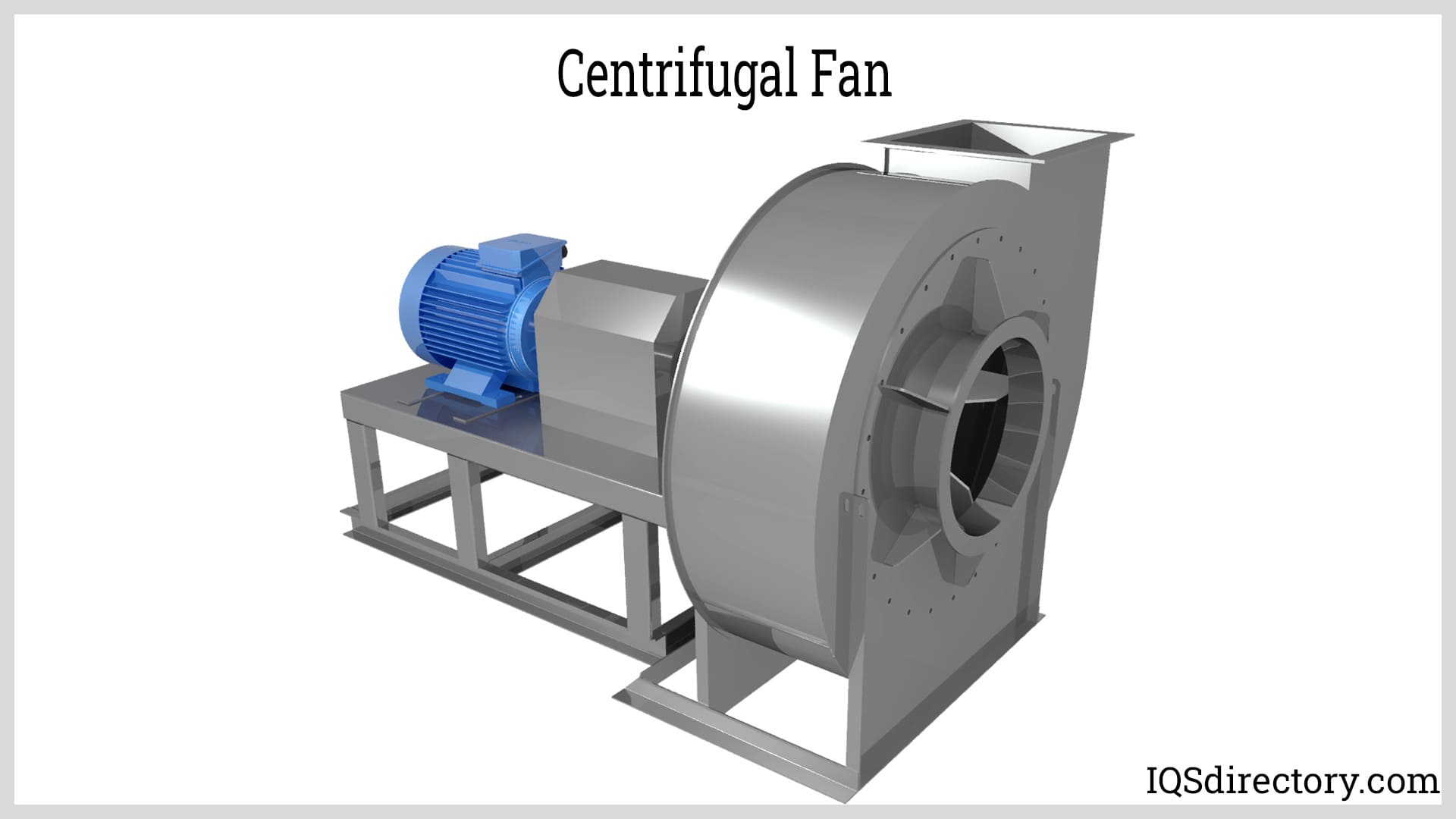

Multistage blowers, which are built with a motor, shaft, and multiple impellers, provide exceptional and unmatched service.

The moving gas or air enters the blower at the stage one impeller and is slowly moved from impeller to impeller until it reaches the appropriate pressure, at which time it exits through the outlet. This basic design is the foundation for all multistage blowers, which vary according to manufacturers and the use of the blower.

An outstanding characteristic of multistage blowers is their reliability, which is one of the main reasons they are used by the oil, biogas, and mining industries. In addition, they can be used to increase pressure or create a vacuum in air and gas applications.

Parts of a Multistage Blower

The multiple impellers of a multistage blower force air or gas into a diffuser with a small area. Speeding up and slowing down the air causes an increase in pressure. The kinetic energy of the impellers increases the volume of the gas or air to move it against the resistance of ducts, piping, and dampers.

- Inlet Volute – The air or gas for the process is sucked into the inlet volute by the rotation of the blower impellers. It is absorbed through the inlet and transferred to the impellers.

- Impellers – The impellers are the main components of a multistage blower. They are balanced and aligned on the blower’s shaft. The various types of impellers include radial, backward curved, and backward inclined. The impellers define the stages of a multistage blower. The number of stages varies depending on the application and pressure requirements. The flow rate can be increased by increasing the diameter of the impellers. In addition, the number of impellers or stages can be increased to create more pressure.

Types of Impellers

-

Open Impeller

With open impellers, the vanes are not covered on either side. They are the weakest impellers and are used with smaller-diameter blowers.

-

Semi-Open Impeller

The vanes of a semi-open impeller are covered by a shroud on one side and free on the other. The shroud adds strength to the impellers, making them more efficient than open impellers. Semi-open impellers must be carefully installed and balanced, with a small clearance between the impeller vanes and the blower casing.

-

Closed Impeller

With closed or shrouded impellers, the vanes are placed between two discs in a single casing. Closed impellers are commonly used with multistage blowers due to their high efficiency. They are precision-balanced and carefully placed to provide sufficient clearance with the blower casing.

-

Shaft

The shaft runs through the center of the impellers and serves as a means of connecting them. It is a stainless steel mechanism that rotates the impellers and is driven by the blower motor.

-

Blower Motor

The power to rotate the shaft and the impellers and pull in the air or gas is provided by an electric motor. The drive mechanism for the motor can be directly connected to the shaft for direct drive or indirectly connected to the shaft by a belt.

A direct drive provides more power but creates increased torque. The RPM and speed of the rotation can be adjusted by changing the speed of the motor. Direct drive motors, which do not have chains or belts, require less maintenance and upkeep.

Indirect drive motors have a belt or coupling that connects the motor to the shaft. The belt allows for variable speeds, which makes indirect drive motors ideal for low-pressure applications. In addition, the torque on the motor is lowered when the motor's power is diverted through the belt.

-

Discharge or Outlet

As air or gas moves through the stages of the impellers, the rotational force increases the pressure in preparation for the release of the air or gas through the discharge flange or outlet. This outlet is located in various positions depending on the blower’s design.

-

Housing or Casing

Generally, the housing or casing for a multistage blower is made of cast iron or steel, with sections connected by steel rods. Lighter metals, such as aluminum, can be used for small multistage blowers.

The list of multistage blower parts outlined above is generic and can apply to any manufacturer's multistage blower. How the various components are assembled, their quality, and their durability depend on the manufacturer. The basic components of any multistage blower are the electric motor, impellers, shaft, and inlets and outlets.

Benefits of Using a Multistage Blower

Multistage blowers are a very versatile and dependable tool that can be configured for any application. By changing the number of stages and the diameter of the impellers, a multistage blower can easily fit any need.

Multistage blowers are:

- Reliable – Of the many characteristics of multistage blowers, their reliability and dependability are two features that are emphasized the most. Multistage blowers require little maintenance and can operate for hours. They also have stainless steel parts and protective coatings that allow them to operate in any environment.

- Safe – Since multistage blowers can operate without manual oversight, they are a safe solution for handling air or gas. They operate noiselessly in any conditions and provide guaranteed service.

- Customizable – Multistage blowers can be configured, engineered, and designed to fit the needs of any application. Along with their reliability, this is another feature that makes them an ideal choice.

- Energy-Efficient – The motors provided to power multistage blowers can operate at fixed or variable speeds and come in several varieties of voltages, depending on the application’s requirements.

- Protected by Cast Housing – Multistage blowers are built as a single unit mounted on a steel baseplate. The closed and sealed housing prevents damage to the blower by the elements, chemicals, or gasses.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services